Neuester Blog

Sacklochbohren von Glas und Polymerbohren Bearbeitung mit UV-gepulsten Lasern

Dec 30 , 2022Blind Hole Glass Drilling and Polymer Drilling Machining with UV pulsed lasers

Blind Hole Machining

By using proprietary laser techniques IPG machines high aspect ratio taper less holes in material thicknesses up to 2 mm. Examples include 25 micron diameter holes in 1 mm thick tungsten and nylon disks, or 50 microns diameter holes in 2 mm thick materials.

Advanced illumination optics are used to condition the laser beam to provide a uniform distribution of energy on the exposed area, typically

better than ± 5 %. This allows machining with extremely accurate depth control since a pulse by pulse, layer by layer, removal process can be used to machine the part with sub-micron level depth control.

UV workstations can be provided for blind hole and through hole drilling, with manual-load, semi-automatic and fully automatic micromachining systems available.

Blind Hole Glass Drilling

Due to its tendency to crack with thermal stress and its transparency, glass is a difficult material to laser drill with high precision. Large arrays of micron scale blind or through holes can be process with sub-micron depth control in materials up to 500 μm thick. Single high repeatability counter bored holes in 150 μm thick glass is one example of a typical production process provided by IPG Photonics.

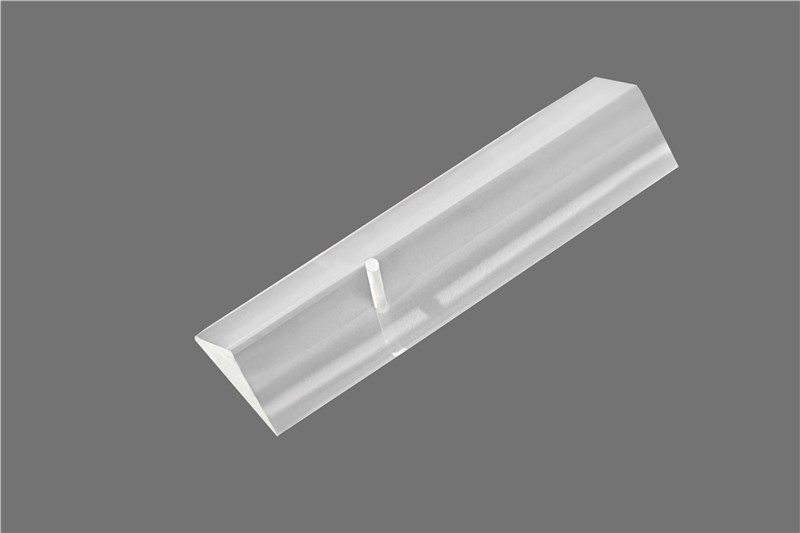

Figure shows blind holes 50 µm diameter up to 400 µm deep in glass.

Blind Hole Polymer Drilling

Arrays of simple or complex mask features can be projected onto the target, and exposed sequentially to produce tridimensional features of various sizes and shapes. Several features may be exposed with a single pulse, and exposure fields can be stepped across the part to achieve large-area patterning

Patterning of Highly-dense Features by UV Ablation

Wenn große Materialmengen mit UV-Licht abgetragen werden müssen, ist die Gesamtleistung des Lasers der Schlüssel für einen hohen Durchsatz. Das Verfahren ist effizient, wenn der Laserstrahl so geformt ist, dass er eine großflächige Maske ausfüllt.

Die Abbildung zeigt eine massiv parallele Sacklochanordnung in Polymer. In diesem Beispiel passen einhundert Löcher mit einem Durchmesser von 4 µm in eine Fläche von 50 × 50 µm. Die minimale Strukturgröße bei diesem Verfahren kann bis zu 2 μm betragen.